Hi all! I’m Jack DiMeo, Clarkson University Class of 2023. I’m a mechanical and aeronautical engineering double major from Granby, Connecticut. I would like to share with you my journey and some of what my professional experiences have been like here at Clarkson. In this post, I’m going to walk you through the types of professional experiences I’ve had and how they’ve impacted my knowledge, skills, understanding, and most importantly, future career opportunities.

When I was trying to choose a college, it really stood out to me how Clarkson students have so many professional experiences when they leave college. There are several different ways to get these professional experiences in college, notably through hands-on research, internships, co-ops, and hands-on design, and competition teams. It’s super important to have at least some combination of these experiences while in college in order to set yourself up for professional success in the future.

The best part is you don’t have to wait to start getting your professional experience and working towards cool opportunities. As a Clarkson student, I was able to get started with gaining professional experience even BEFORE I started my first semester of college. So far I have had a multitude of different experiences that are all standouts on my resume and really help me take what I am learning in the classroom to the real world and vice versa.

Doing Research in College

Being in the Honors Program here at Clarkson I was presented with the opportunity to complete a five-week research program prior to my freshman year. This took place the summer before I started my first semester. The Honors Program is a highly selective research-based program for students looking to be challenged academically and participate in a living-learning community of like-minded students.

After inputting some preferences I was matched with Dr. Ken Visser and his Wind Energy and Aerodynamics Laboratory in the Mechanical and Aeronautical Engineering Department at Clarkson. My first summer I was assigned, along with two other undergraduate students, the task of evaluating cambered plate and low profile airfoils for their use at low Reynolds numbers.

From there I continued my research working with other undergrads throughout my freshman year on various projects. Eventually, I was able to collaborate with a fellow undergraduate student, Aaron Kummer, to publish a paper in the IOP Journal of Physics. The paper was titled “On the Use of Cambered Plate Airfoils for Small Wind Turbines” (check it out here).

Throughout it all, my underlying project has been to develop a new cambered plate airfoil that is more effective than the currently used GOE417a. It has really been a great experience and I have been able to develop great relationships with other students in the lab and professors working on the project.

It’s so amazing that right from the beginning I was able to get started working hands-on in research through this program, and now am able to work as an intern for Dr. Visser’s company, Ducted Wind Turbines, Inc. (which I’ll get into more detail if you keep reading!).

Getting a Co-op in College

First off, I should probably answer the question: What is a co-op? A co-op is a paid, full-time experience at a company or organization in replacement of your college semester on campus. It should be related to your major or area of study and at Clarkson, you do not pay college tuition during this time.

In the fall of 2020, I worked on CO-OP with GE Aviation in Lynn, Mass. At GE Aviation, I was a Combustion and Structural Components Intern working on the floor in Punch Press. I often get asked how I managed to get a CO-OP so early in the fall of my sophomore year. A great part of the Clarkson culture is the availability of resources like the Career Fair and the Career Center. Prior to the Career Fair, the Career Center put on a series of events in which I was able to speak with a GE representative and develop a connection. That said, at the career fair itself I already knew the rep. and was given the opportunity to interview!

This was an interesting position because of where my role was in the manufacturing process. I was at the very beginning of the process, working in the area where they turned sheet metal into the individual parts to make the afterburner liner for the F414 engine that is used in the F18 super hornets of the US Navy.

I was responsible for developing a tracking system for the dies and gages going through their calibration cycles. Being able to have this experience has been great. My favorite experience there was getting to see an Engine test of the same type of engine my plant was making parts for.

Getting an Internship in College

Having had the opportunity before I started freshman year to work in the Wind Energy and Aerodynamics Laboratory under Dr. Visser, it was a natural fit for me to take on an internship with his company, Ducted Wind Turbines (DWT) this summer as an Engineering Intern. Ducted Wind Turbines is a start-up company that Dr. Visser started out of his research to make commercial production of better, more accessible wind turbines. So far it has been a great experience, exposing me to the field, along with desk work, and allowing me to see the multi-faceted parts of being a mechanical engineer in the startup space.

My internship grew out of my research, allowing me to not only continue what I was studying but also expand my view of the whole business as an internship.

I decided to continue my research project which focuses on designing new cambered plate airfoils that are more efficient than the GOE417a currently being used on the ducted wind turbine.

My internship has been a whirlwind of sorts in the most positive sense I can think of. It has been an incredibly different culture and experience than working with GE previously.

In this internship, I have been able to work on several different projects. The first, and most prominent has to do with analyzing the data coming off the prototype turbine at the Clarkson Test Site. I have been tasked with rewriting and improving a code to calculate the relevant information and plot the appropriate details. This plays into discussions about control systems improvements and overall downstream electrical considerations.

Additionally, I have worked to improve the manufacturability of the turbine’s electrical system. While this is slightly out of my wheelhouse it has been a good learning experience. Lastly, I have been able to participate in turbine installs and reworks. This has been great because it allows me to be hands-on with the tools in the field which is something I hope to continue into my career as a mechanical engineer.

Participating in Competition Engineering Design Teams in College

In college, you get many different types of experiences that all help you both in class and in preparation for your career. I think it’s so important to get outside of the classroom experiences and am grateful for all the different opportunities I have been given.

Another one of these experiences that have been so helpful has been participating in a SPEED Team. SPEED stands for Student Projects for Engineering Experience and Design, and we have a lot of different team projects going on here at Clarkson. Each of the team’s has the opportunity to compete at the regional, national or international level against other colleges and universities, and Clarkson teams have done very well recently.

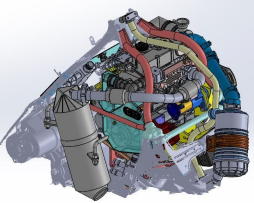

I participated in the SAE Clean Snowmobile SPEED Team and worked hands-on in the mechanical engineering lab. My role with the SPEED team was limited, however, I really enjoyed working on the project. I helped to design a new air filtration system to fit the diesel engine into the snowmobile chassis.

I found that being in a SPEED team allowed me to get great hands-on experience and allowed me to be around other people who have similar interests as me. I met a lot of great people while doing it and would love to be more involved in the future if I can find the time.

Final Thoughts on Having Professional Experiences in College

Overall, I feel excited, and proud of all the different ways I have been able to gain experience and hands-on practice here at Clarkson already. What’s really nice is how these opportunities have created great relationships with professors and other students. As mentioned, my work with Dr. Visser has led to many opportunities. He, among other faculty, wrote letters of recommendation for my scholarship applications, and I trust him on all matters of my education and career. It’s nice to know that I have such a great support system here.

I know that the work I am and have been doing with Dr. Visser has helped me learn differently, and really allowed me to take more away from my curriculum. I have been trusted to accomplish my work and develop skills on my own since the beginning. Not being “babied” through the process has forced me to develop critical thinking skills that I would not have otherwise. Additionally, he has always encouraged me to seek out information on my own rather than just giving me the answers. I would say it’s not unique for a Clarkson student to have this type of relationship with our professors, however, I do think it’s a critical part of our development as future professionals, and what makes Clarkson unique.

When I was looking at Clarkson University, It was clear that here, and only here. Was I going to be provided with all of these opportunities, presenting me with a variety of professional experiences throughout my undergraduate career, and uniquely early on.